Test rigs for joint permeability, watertightness and wind load behavior on exterior building components

Windows, facades, external pedestrian doorsets and gates are on the weather front. Will they stay tight?

The test rigs are used to determine the joint permeability, watertightness and wind load behavior of windows, doors and facades. Sealants, panels and other exterior wall components can also be tested for the above characteristics.

The test rigs can be ordered as ECO or PROFI version and consist of a measuring and supply unit as well as a clamping field. The ECO window test rigs are optimized for use in manufacturing plants for regular factory production control (FPC) or for development testing. For daily use in test or customer laboratories we offer the version "PROFI". Further features, technical data and information on the accessories of the test rigs can be found on this page.

The advantages at a glance

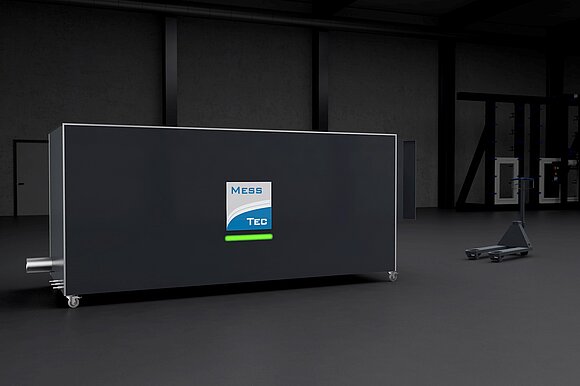

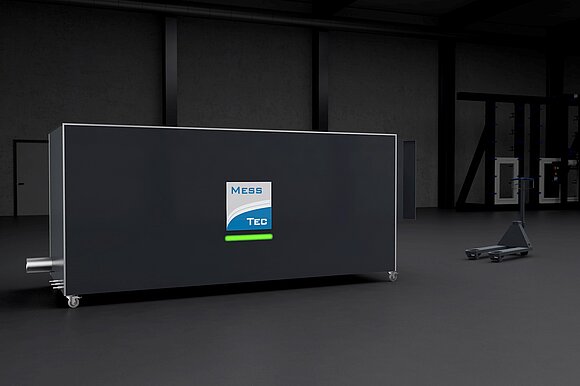

Measuring and supply units (MSR)

Our measuring and supply units (MSR) are equipped with an integrated air fan to create testing pressure and measure the permeability

of joints. In conjunction with measuring tubes, the speed-controlled air fan can directly measure the air mass flow in m³/h required according to standards. For increased accuracy, temperature-controlled sensor boxes are used in the PROFI versions and in the EcoPlus option. The measuring accuracies and long-term stability achieved guarantee safe use for official tests and calibration in the accredited area (DAkkS).

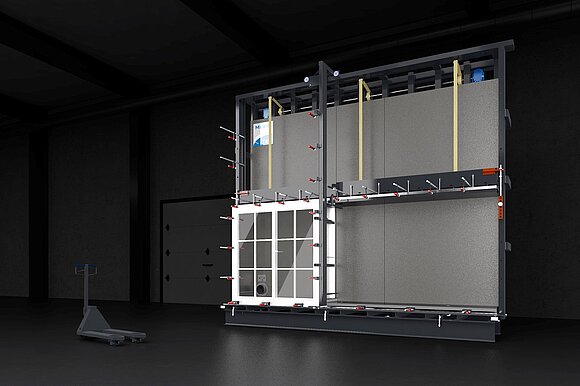

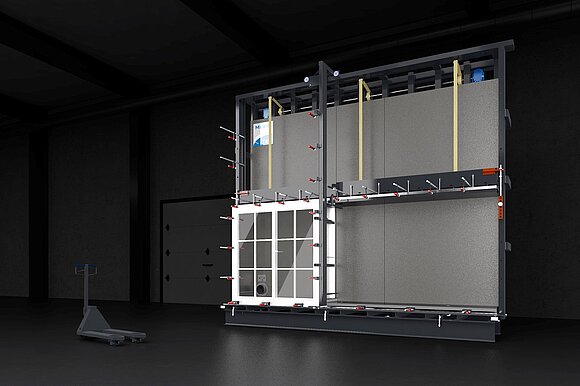

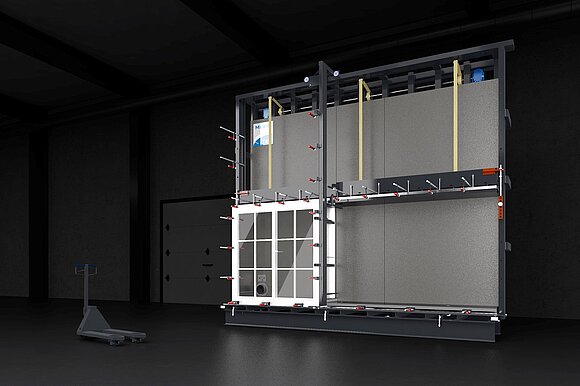

Clamping surface (ASW)

In the case of the clamping fields, the ASW-ECO version is designed for testing air permeabilityand water tightness as well as smaller wind loads. With the ASW-PROFI product series, higher wind loads above 3000 Pa can also be applied. The extremely stable structural steelwork allows wind loads of hurricane strength as well as extreme specimen dimensions and weights.

Clamping is always done by an electric driven horizontal bar, variable moving side element and the tool-free fast tension system of ift MessTec. Long term use of the sealing of the test rig elements and the test specimen is ensured by the block seal in EPDM-quality. All metal parts that come into contact with the test water are made of stainless steel. Durable waterproof special plates are used for the back wall. The variable moving side elements can be screw-fastened for high test pressures. The built-in siphon can be additionally closed by a shut-off valve in case of high pressures.

Testing possibilities (standards and directives)

National + EU

| Windows/doors - test standards | |

| Test according to product standard EN 14351-1 | |

| Air permeability | EN 1026 |

| Water tightness | EN 1027 |

| Resistance to wind load | EN 12211 |

| Operating forces windows/doors | EN 12046/EN 12217 |

| Resistance to racking | EN 14608 |

| Resistance to static torsion | EN 14609 |

| Load capacity of safety devices | EN 14609 |

| Impact resistance | EN 13049 |

| Mechanical durability | EN 1191 |

| Curtain walling - test standards | |

| Test according to product standard EN 13830 | |

| Air permeability | EN 12153 |

| Watertightness tightness static/dynamic | EN 12155/EN 13050 |

| Resistance to wind load | EN 12179 |

| Impact resistance | EN 14019/EN 12600 |

International methods

| Test according to ASTM /AAMA | |

| Air Leakage | ASTM E 283-04 |

| Water Penetration static/dynamic | ASTM E 331-00, AAMA 501.1-05 |

| Water Penetration (Hose test) | AAMA 501.2-03 |

| Resistance to wind load | ASTM E 330-02 |

| Seismic-Structural Movement static/dynamic | AAMA 501.4-00, AAMA 501.6-01 |

| Thermal Cycling | AAMA 501.5-07 |

| Test according to CWCT | |

| Air Leakage | Section 5 |

| Water Penetration static/dynamic (aircraft propeller/wind generator) | Section 6, 7, 8 |

| Water Penetration (Hose test) | Section 9 |

| Wind resistance (serviceability/safety) | Section 11, 12 |

| Impact safety | Section 15 |

| Seismic-Structural Movement | Section 17 |

| Thermal Cycling | Section 18 |

Product details of our window test rig

MSR-ECO:

- Power: 2 to 15 kW

- Required supply: Compressed air or blower

- For FPC or development testing

- ECOPLUS option is appropriate for official tests

- Air fan controlled with frequency converter

- Comprehensive MS Windows software LWW

- Installed in mobile, closed housing

- One water metering and control circuit 50 l/min (can be extended as required)

- Differential pressure measurement up to ± 2500 Pa (expandable up to ± 10000 Pa)

- Test air measurement based on standard values: 0.5 to 100; 150; 250; 400; 500; 800 m³/h

- Deformation transducer 50 or 100 mm (standard)

- Integrated test air switchover, pressure/suction switchover and exhaust air damper

- Standard connections:

- CEE 16/32 A (without RCD - Fi)

- Fresh water depending on size: 30 to 500 l/min - 4 bar

- Waste water connection depending on size: 50 to 150 mm

- Compressed air 4 bar / 1" line (clean and oil-free)

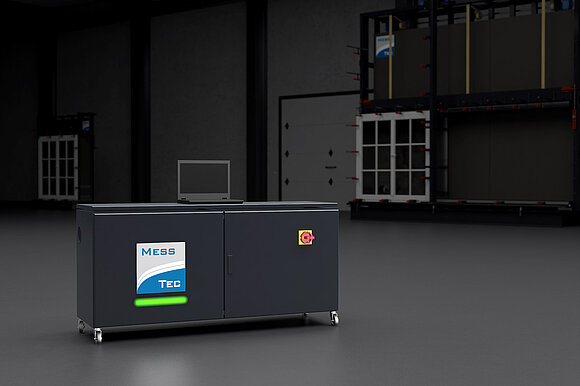

MSR-PROFI: like MSR-ECO with the following deviations

- Power: 20 kW to 160 kW

- Blower supply only

- Standard already appropriate for official tests and calibrations in the accredited area

- Equipped with 2 or 4 water circuits á 80 l/min (customer configuration possible)

- Differential pressure measurement up to ± 5000 Pa (can be extended to ± 20000 Pa)

- Special versions such as cyclical water tightness tests according to Chinese standards experts can be integrated

ASW-ECO:

- Clamping surface sizes; 2x2.5; 3x3; 4x3 (W x H in m)

- Structural steelwork in RAL 7016 color coated

- Rear wall and screen abutments made of waterproof body panel

- Stainless steel base plate

- Bar lift via electric winch

- Siphon with shut-off ball valve

- Air inlet, pressure measurement connection, water and, if necessary, fog connections made of stainless steel

- Sufficient ift MessTec clamps (tool-free, quick adjustment, individual tightening force) according to size

- The test wall is usually delivered in two parts and assembled in one day

- Support tubes or mobile carriages are available for the displacement transducers

- Sprinkling pipes with 2 l/min or 1 l/min, 120° full cone nozzles with a distance of 400 mm are included. The sprinkler pipes can be continuously fixed to the included stainless steel fixing devices. Any element width from 500 mm can be ste up.

- Pressure range up to max. ± 3000 Pa (size restriction)

ASW-PROFI: like measuring and regulating unit ECO with the following deviations

- Clamping surface sizes 3x3; 4x3.8; 5x5 (W x H in m) and customized max.: W: 10 m H: 10 m

- Very stable structural steelwork in RAL 7016 color coated

- All side elements made of stainless steel elements (screwable)

- Pressure ranges up to max. ± 20000 Pa possible (with additional equipment)

- Electric driven horizontal bar lift via textile belts with FU and lifting gear - side elements can be lifted with the bar

- Delivered in individual parts (increased assembly effort from 4 man-days)

We customize your window test rig according to your wishes and requirements. The following accessories are available for our window test rigs:

- MSR ECO-PLUS - extension of the MSR-ECO to official tests

- Extended measurement instrumentation, software extension, additional costs for DAkkS calibration

- Displacement transducers with 50, 100, 200, 300, 400 or 500 mm

- Displacement transducer rail for vertical fixing of three displacement transducers

- Transducer carriage for vertical and 1.8 m horizontal transducer mounting

- Extended pressure measuring range:

max. test pressures: ± 20000 Pa - Water circulation for steady fresh water supply(incl. water pump, collection tank and control unit) 30, 60, 150, 300 and 500 l/min

- Additional water metering and control circuits (50 or 80 l/min each)

- Additional sprinkler pipe (required from 2.5 m test specimen height) (incl. nozzles 1 l/min; hose with T-connector)

- Additional spray devices or irrigation facilities for facade testing

- EN wind generator unit for dynamic wind loads according to DIN 13050

- Wind generator for dynamic wind loads according to AAMA

- Factory or DAkkS calibration:

- Air pressure

- Air flow

- Water flow rate

- Displacement transducer

- Temperature and climate control devices

- incl. air circulation

- incl. insulating of test wall and side elements

- optionally with humidity control

- With heating/cooling capability of approx. 3 kW, 4 kW, 5 kW, 10 kW and customized

- Temperature range -10...+60°C; -20...+80°C and customer-specific

- Fog machine with external manual control and pipings

- Resistance to static torsion according to EN 14609 and to loads in the door level according to EN 14608 (racking and torsion) Download product data sheet)

- Additional test for safety devices (incl. measure unit with display and hand winch)

- Small compressor for own compressed air generation

- Increased test chamber depths to 400 mm: 600 mm, 800 mm, 1000 mm

- Access hatch: 450 x 1200 in mm (only for test wall depth 600 mm)

- Clamping frame with floor slab simulation for small facades

- Dual tire impactor with deflection device for impact tests

- Mobile compact measure units for surrounding conditions (air pressure, humidity and temperature)

- Mobile compact measure units for the determination of operating forces

- Setting up remote access via the Internet

- Remote test equipment digiTEST

- Equipment for customer test walls (windows and facades)

- Changeover equipment for the connection of several test walls to one measuring and regulating unit

- Conversion, modernization and repair of old test rigs (also third-party products)

Individual additional equipment specifically for your needs can also be offered according to your requirements.

Test module LWW-ECO

These test rigs have been optimized for use in manufacturing plants for regular factory production control (FPC) or for development testing. Thanks to their lightweight structure, the test walls can be assembled in just one day. However, with the ECOPlus option, the measuring and regulating units can also be extended for official tests.

Test module LWW-PROFI

These test rigs are designed for daily use in test or customer laboratories. The measurement and supply unit is equipped with very high-quality measurement instrumentation and a large blower with ± 5000 m³/h volume flow and ± 10000 Pa pressure range. Two or four 80 l/min water control circuits are fitted as standard. All European or international standards can be tested with the supplied software and hardware. All sensors can be confirmed with a DAkkS calibration by the independent ift calibration laboratory in the accredited area according to EN ISO 17025. Increased accuracies for international standards such as ASTM or CWCT can also be covered on request.

The associated ASW-PROFI test wall is designed for use with heavy and large test elements. High wind loads and extreme dimensions can also be generated with these test walls. Individual specifications such as dynamic wind loads on industrial, commercial, garage doors etc. can also be covered. A wide range of accessories is also available for concrete facade test stands from clients. These range from spraying equipment to a 600 HP blower with propeller.